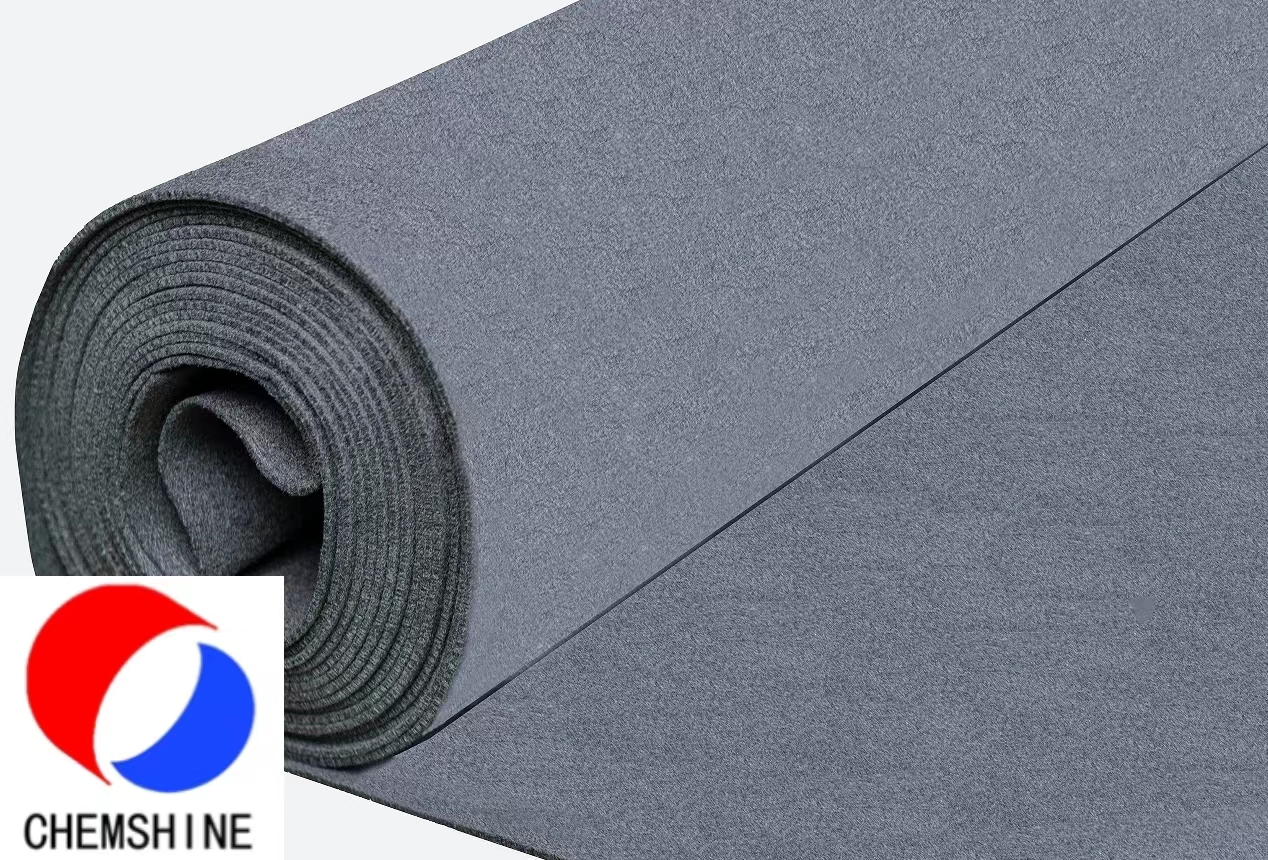

RAYON BASED GRAPHITE FELT

Chemshine based on domestic/imported polypropylene based and rayon based materials, all are processed in a one-stop process from raw silk weaving white felt, pre oxidation, carbonization, graphitization, surface treatment, etc., following the ISO9001 quality system, ensuring stable quality in every production process, with shape retention, no volatilization, no fiber shedding, low thermal conductivity, and long service life.

Category Adhesive based ink felt

Online consultation

Online consultation

Product Details

The rayon based graphite felt is made using a unique airflow forming technology, ideal fiber network structure with

high uniformity and chemical properties, and a special manufacturing process with good felt stretching and strength.

The resulting graphite soft felt has high insulation and high purity. Advantages:

●Good high-temperature insulation

●Outstanding thermal stability and low coefficient of expansion

●High purity, low impurity content

●High uniformity and uniform thickness

●Corrosion resistance and long service life

Application: Mainly used in high-temperature environments under vacuum or inert gas protection, such as SiC induction

furnaces/resistance furnaces, silicon single crystal/polycrystalline furnaces, high-temperature sintering furnaces, fiber optic

rod making/drawing towers, thermal high-temperature furnaces, and other performance indicators.

RAYON BASED GRAPHITE FELT Technical Specifications |

technical Indicators | Unit | technical parameters |

volumn density | g/cm³ | 0.06-0.10 |

thickness | mm | 5/10 |

width | mm | 1200-1400 |

length | mm | 3000-12000 |

production temperature | ℃ | >2200 >2500 |

thermal conductivity(25℃) | W/(m·K) | 0.04 0.04 |

thermal conductivity (1000℃) | W/(m·K) | 0.11-0.13 0.11-0.13 |

Impurity Parts per million | PPM | <200 ≤5 |