Innovation points and process parameters

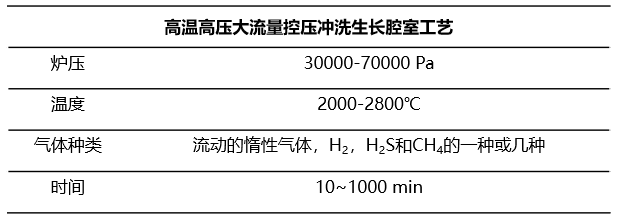

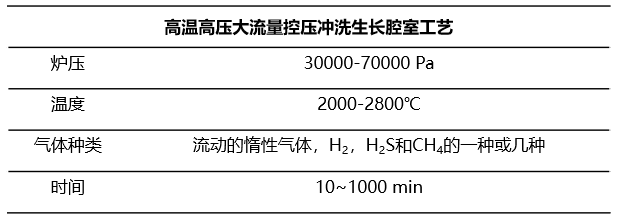

In view of the above issues, by adding a high-temperature, high-pressure, high flow rate controlled pressure flushing process to the growth chamber before the growth of silicon carbide crystals, the impurity concentration in the growth chamber system can be effectively reduced, thereby obtaining high-purity semi insulating silicon carbide crystals. The relevant process parameters are as follows:

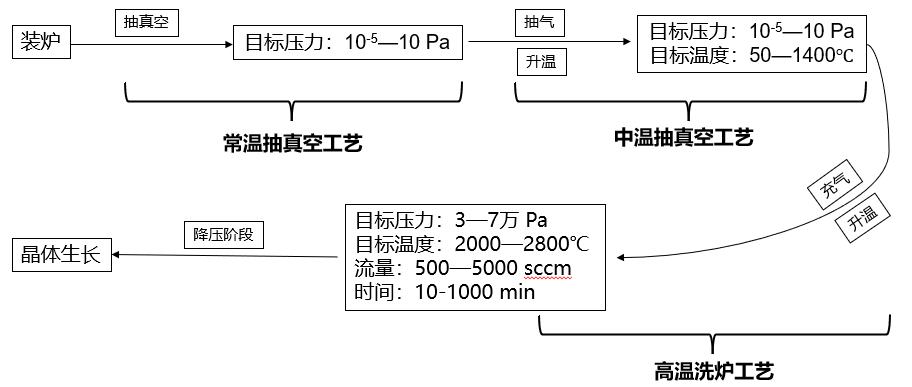

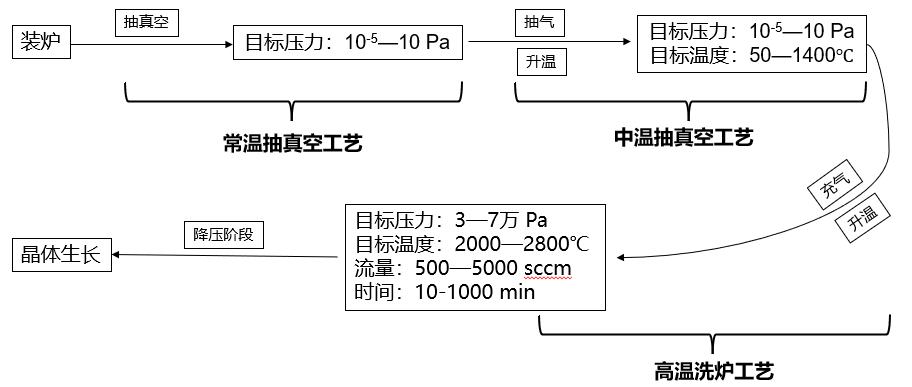

Process Flow Diagram:

Process analysis

The present invention adopts a key process of high-temperature, high-pressure, and high flow flushing chamber before the growth of silicon carbide crystals. High pressure can effectively protect the silicon carbide seed crystals from damage, and high temperature can also cause nitrogen, boron, and other impurities adsorbed in the system to evaporate or desorb. High flow flushing can effectively remove nitrogen, boron, and other impurities in the evaporated or desorbed state. In particular, high flow flushing gas can enter the pores of graphite parts and insulation felt in the growth chamber, effectively removing impurities adsorbed on porous insulation felt and graphite parts, further reducing impurities in the growth system. The present invention can greatly reduce the impurity content in the chamber system before the growth of silicon carbide crystals, thereby obtaining high-quality high-purity semi insulating silicon carbide crystals.

experimental result

Compared to crystals grown by conventional processes, the impurity content is significantly reduced; Impurity N decreases by 1 to n times, and impurity B decreases by 1 to 2 times. The resistivity has significantly increased, by 1-3 orders of magnitude.

From the process flowchart, it can be seen that the depressurization stage before crystal growth requires careful design. If the temperature is too high, a suitable cooling rate needs to be matched during the pressure reduction process.